Create A Book - It's easy using Red River Paper!

Photography is still the best way to make time stand still. Now that you have a mini-printing press on your desk think of ways to use it for creative and fun projects. Pick a set of photos you like and make a book!

Red River Paper offers a wide variety of inkjet papers you can use to print and bind custom books. You can choose from glossy, semigloss, matte, and even cotton art papers for your book project. This Print Something article offers suggestions for how to bind your book and what to expect from each process.

Definition: Binding is a general term for any of the various methods of securing or binding together the loose pages or sections of a book or booklet using stitching, staples, wire, plastic, tape, or glue.

When paper clips won't do

If you are printing a booklet, book, or multi-page report, you need to plan how you will put together the finished product before you set up your document in your page layout program. You can choose from several binding methods, each with its own pros and cons depending on the purpose of the document, the need for durability and best appearance, and cost.

For some binding methods, it might simply be a matter of ensuring that the margins are wide enough to accommodate the holes for a three-ring binder or spiral binding. For saddle stitching, you may need to compensate for creep. Some bindings provide more durability, while others allow your book to lay flat when open. You will also want to weigh the cost of special equipment if you want to do-it-yourself rather than using a local copy shop or printer for your binding and finishing.

Below, we look at several methods to consider when it is time to bind.

Binding Methods

Comb Binding

Definition: Comb binding is a method of securing loose printed pages using a piece of plastic with "teeth" that fit into rectangular holes in the paper. Comb binding is somewhat similar to wire spiral binding.

Also Known As: plastic comb binding

Resources: Comb-binding machines can be purchased a local office supply stores. A quick glance at Amazon found a selection of comb binding machines from $49 to $699.

Have someone do it for you - Office Max, Office Depot, and FedEx Office offer in-store business centers that can bind your books for a nominal fee.

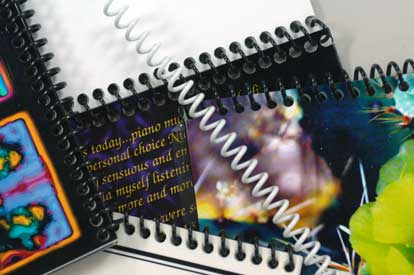

Spiral Binding

Definition: Spiral binding is a method of securing loose printed pages using single or double-loop wire or plastic that fits into round or rectangular holes in the pages. Spiral binding is often used for blank notebooks and for reports that generally have a short shelf-life. Spiral binding allows the publications to lay flat when opened.

Also Known As coil binding, wire spiral, double loop wire binding, Wiro (brand name for double loop wire), Wire-o

Resources: Local office supply is a convenient place to get spiral binding done. Machines that do this sort of binding have become quite affordable over the past few years. You can buy a nice one for around $135, and you can also find them on Amazon.com: TruBind Coil-Binding Machine – TB-S20 – Professionally Bind Books and Documents – Office or Home Use – Adjustable Hole-Punching and Paper-Size Settings

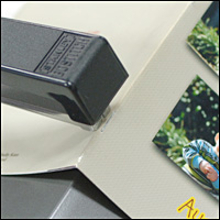

Saddle-Stitched

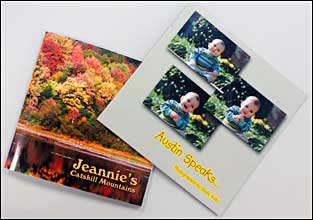

The above custom books were printed with two Red River inkjet papers. The cover is a 68lb. UltraPro Gloss 2.0 and the interior pages are 32lb. Premium Matte Double-sided.

Definition: Saddle-stitched is a method of securing loose printed pages with staples down the middle of a folded sheaf of paper. Many booklets are saddled-stitched. Side-stitching is a similar method where the pages are stapled about 1/4" from the spine.

Also Known As: booklet making, staple-stitched

Resources: Saddle-stitch staplers are available locally and online.

Perfect Binding / Thermal Binding

Definition: The method of bookbinding where a flexible adhesive attaches a cover to the spine of the assembled signatures is called perfect binding. Paperback novels are one example of perfect binding. Variations of perfect binding are where the cover is glued only to the side of the spine and allows the book to lay flat.

There are numerous companies that serve this space. A great example is UniBind, which offers both Thermal Binding Machines and Hard Covers. There are many Other Thermal Binding Machines and cover options that include soft, clear, and more.

Specialty Binding - Use Your Imagination

Chicago Screw Custom Binding

Take a series of printed images of any size and come up with a fun way to bind them using one or more screw-posts or "Chicago Screws". This is a particularly easy way to quickly assemble images for viewing with little worry about registration, alignment, or other book-binding issues.

Ring Binding

>

>Definition: Ring binding is a method of securing loose printed pages in soft or hard-covered books with rings that hold the pages through holes punched in the pages.

Examples: Ring binding is often used for procedural manuals or documentation where changes are frequently made - obsolete pages are removed, and replacement pages are easily added in.

Also Known As: notebook binding, three-ring binders

Stitch Binding - Tips from Frank Hamrick

Frank Hamrick is an associate professor at Louisiana Tech University. His work mixes photography, storytelling, handmade books, and found objects. Frank received his BFA from The University of Georgia and his MFA from New Mexico State University. NPR has written about Frank’s handmade books, and Oxford American Magazine listed Frank as one of the 100 Superstars of Southern Art. His work is housed in collections including The Art Institute of Chicago, The Amon Carter Museum of American Art, and The Ogden Museum of Southern Art.

Below is Frank's discussion on his process for custom book printing and binding. It is not a definitive guide but rather his take on how he prefers to make special custom books.

=====

I print my images via Photoshop.

I use the full-size sheets of paper as they come in the box. If needed, I trim the paper to the size I want the book spreads after the images have been printed and their surfaces have been sealed with a fixative.

If I am making a twenty-page pamphlet book, then my canvas layouts in Photoshop are pages 20 & 1 on one side of the double-sided paper and pages 2 & 19 on the opposite side of the paper.

Pages: 18 & 3, 4 & 17

Pages: 16 & 5, 6 & 15

Pages: 14 & 7, 8 & 13

Pages: 12 & 9, 10 & 11

The images are all in the same color profile and are already the proper size and sharpened when I lay them onto these page spreads.

I inkjet print images on one side of the double-sided matte paper and then let them dry for 24 hours while they are sandwiched between sheets of regular copy paper.

Spreads: 20 & 1, 18 & 3, 16 & 5, 14 & 7, and 12 & 9

Waiting 24 hours to dry helps keep those first set of images from getting smeared when the paper is run through the inkjet printer a second time and also reduces the risk of those prints offsetting ink onto the printer’s interior rollers and transferring to future prints.

Then after the paper has had 24 hours to dry, I inkjet print the page spreads on the opposite sides of the double-sided paper.

Spreads: 2 & 19, 4 & 17, 6 & 15, 8 & 13, and 10 & 11

I then let these prints dry for 24 hours while sandwiched between sheets of regular copy paper.

Then, I pin large pieces of newsprint paper to the studio wall and pin the printed double-sided matte paper on top. I wear a mask over my mouth and nose while I spray the prints with a fixative made for sealing and protecting photographs; this is similar to what is used to seal charcoal sketches if you have ever taken a drawing class. Wait 15 minutes or so, and spray another layer of fixative. This helps prevent the ink from one image from offsetting onto the neighboring page when the sheets are folded, collated, and bound into book form.

Once that first side is fully dry, time varies depending on the fixative used, I flip all the pages over and repeat spraying two coats of fixative on the opposite side of the double-sided paper and let it fully dry in the same manner.

Once fully dry, I will use an art brush to clean prints to clear off any excess fixative that usually presents itself in the form of white dust.

Then I trim the paper to the size I need the spreads to be so I can use a bone folder to score and fold the gutter in each page spread, collate, and bind the spreads into my photography books.

Scoring each page individually before folding helps minimize cracking. Also be aware when a page is scored, you fold the page spread down and away from the indention scored into the paper’s surface, not up towards the score. Look at a cereal box or a box of crackers, and you will see what I mean.

I use an awl with a consistent diameter shaft to pierce the sewing stations in the gutter of each individual spread for the stitching. When piercing the page spread, I hold the folded page spread up like the roof of a house and push the awl up from within. This helps the point of the awl go straight up through the gutter. If you punch down with the paper on a tabletop, there is a greater risk of the awl going in at an angle and coming out the opposite side of the paper on the page rather than through the folded gutter.

I use a book binder needle with a rounded point and Irish linen thread to stitch together the book’s end sheets that surround the collated page spreads before ultimately gluing the pamphlets into their hardcovers.

Frank Hamrick

Photography & Book Arts

frankhamrick.com

etsy.com/shop/frankhamrick

Papers to Consider for Book Making

50lb. Arctic Polar Luster Double-sided

32lb. Premium Matte Double-sided

50lb. Premium Matte Double-sided

68lb. UltraPro Gloss 2.0

68lb. UltraPro Satin 4.0

Last updated: November 29, 2023